Biomass Fuel DryerResults Guaranteed as Promised

BRAND: KAYUTAH

MODEL: SFDS5

Production Capacity: Varies between 1 to 20 tons

Moisture Content before Drying: ≤ 60%

Moisture Content after Drying: ≥ 10% (Can be Tuned to desire moisture)

DESCRIPTION

KAYUTAH

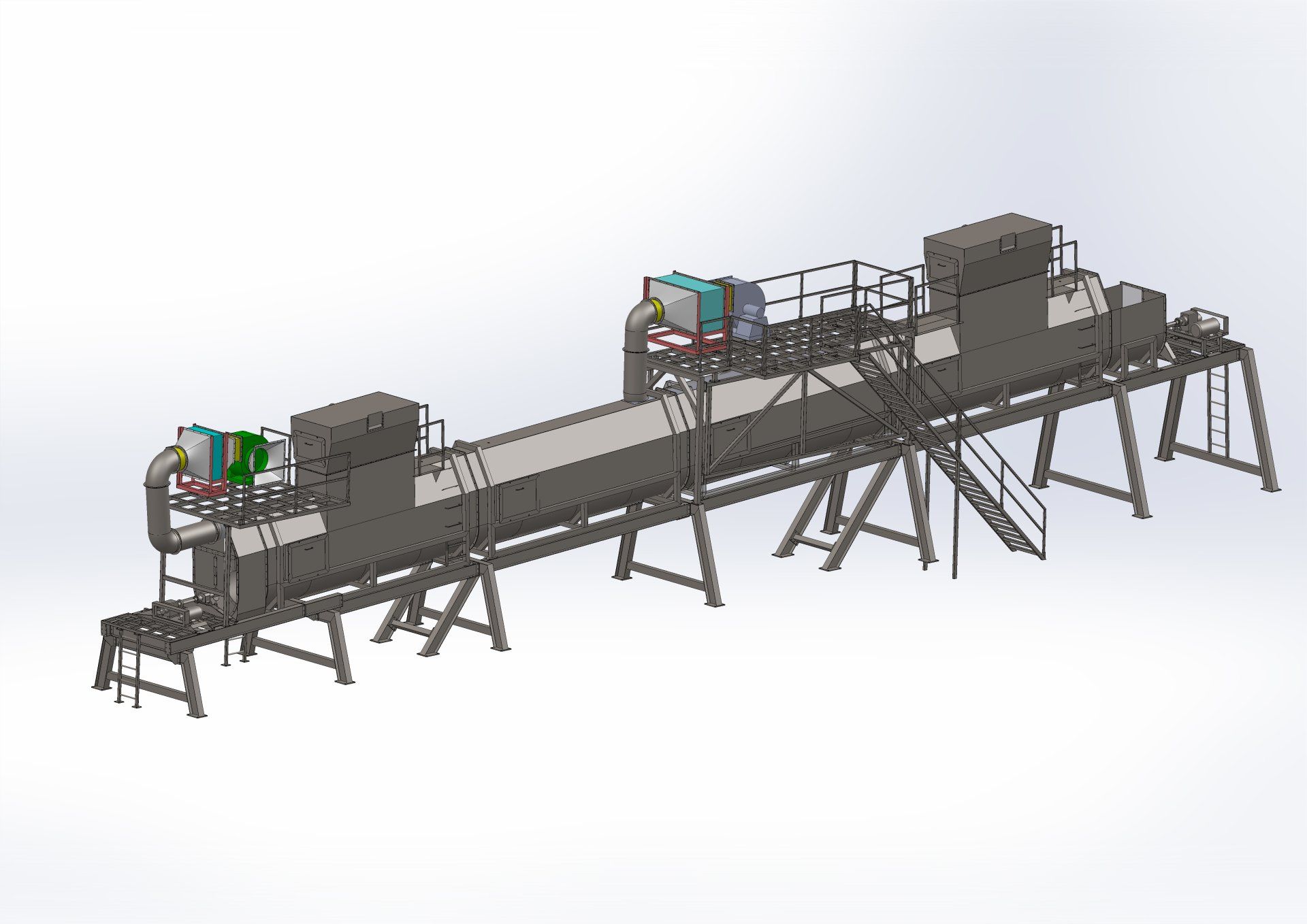

Palm Short Fibre/Woodchips Dryer (Model: SFDS5)

basically utilises all the patent pending drying techniques we have developed in-house over the years in drying Palm Long Fibre. Customers will be able to choose the final moisture content of the palm short fibre with as low as 10% from as high as 60%.

Besides drying palm short fibre, SFDS5 can also dry woodchips (tropical/rubber wood). Even better, a mixer can be located in front of SFDS5 to mix both woodchips and palm short fibre and both biomass can be dried simultaneously.

SFDS5 mainly targets biomass fuelled boilers which are using either palm short fibre or woodchips that has high moisture content especially during rainny seasons.

The layout of SFDS5 is extremely versatile and can be fitted into any part of any factory as each model is custom designed to suit to different purposes. Our site engineer will first obtain a footprint of the factory layout before proceeding to design the layout of SFDS5. We will also ensure SFDS5 will seamlessly fits into any system.

Production capacity varies as different customer has different requirements. SFDS5 will have no problem drying 1 to 20 tons of palm short fibre containing 60% moisture to 35% in an hour.

The major advantage of SFDS5 is it is able to provide a clean working environment with the help of a custom designed suction system. Besides minimal workforce is needed as multiple attachments such as moving floor can be adequately added to the system to allow full automation.

Below are the summarized statistics of SFDS5:

(1.1) Drying Drums (Generation 5)

- Patend Pending Screw Propelling Drying System

- Palm Short Fibre will be able to obtain moisture as low as 30% from 60%

- Easy Maintainance

- Minimal Maintainance

- Comes with proper platform, stairs and hand rails

- Multiple manhole doors for easy maintainance

(1.2) Steam Powered / Thermal Oil Heat Exchangers

- Fully imported from Denmark

- Steam Powered

- Minimum Running Pressure : 7 Bars

- Steam Consumption : Approx 1 ton per hour - Thermal Oil Powered

- Inlet temp : 280 Degree Celcius

- Outlet temp : 255 Degree Celcius

- Volume : 11.24 L/S

- Pressure Drop : 30kPa

(1.3) Cyclone Dust Collecting System

- To prevent dusty working environment

- To collect very fine dust

- To remove moisture from Drying System

(1.4) Control System

- Fully automated controlled by PLC

- User friendly can be fine tuned

- Touchscreen function

- Can be adapted to any existing system

For more enquiry, please contact us via

email kayutah.engr@gmail.com or call us at +6011-1237 9725